Sol Cookware

SOL Cookware represents a line of simple, affordable, and aesthetic at-home kitchen items designed with a single hand in mind but useful to all.

Each item of the line was designed in cooperation with an individual of a culinary background whom in their lifetime suffered from a stroke, resulting in hemiparesis (loss of function on one side of the body).

Cutting, rinsing, transporting, and cleaning represent 4 of the hardest tasks to accomplish when limited to a single hand. SOL Cookware aims to make these tasks once again simple, getting you back into the kitchen.

Meeting a Legend

Mr. Smith is an award-winning chef from South Louisiana and for 42 years pumped out some of the most incredible dishes around. In his 60s, he suffered a stroke and sustained hemiparesis as a result, forcing him into retirement.

Understanding the Problem

Hemiparesis - /heməpə’rēsəs/

paralysis of one side of the body

I will never be able to truly understand the difficulty of living with such an affliction, but after spending time with Mr. Smith over the course of this project, I felt I knew enough to try and make things a little better.

As you can imagine, there’s not much in the kitchen that you do with only one hand. I wanted to help change that.

Major Complaints

1. Washing dishes: Requires one hand to hold the dish and another to scrub the item; Large items become too cumbersome to handle, especially when soapy

2. Rinsing + Transporting: Effectively rinsing produce such as lettuce is awkward; Moving items to and from the cutting board becomes an issue

3. Cutting: The inability to hold items on the cutting surface becomes a safety concern; Current cutting boards on the market are dangerous, ineffective, not user friendly, or cost-prohibitive

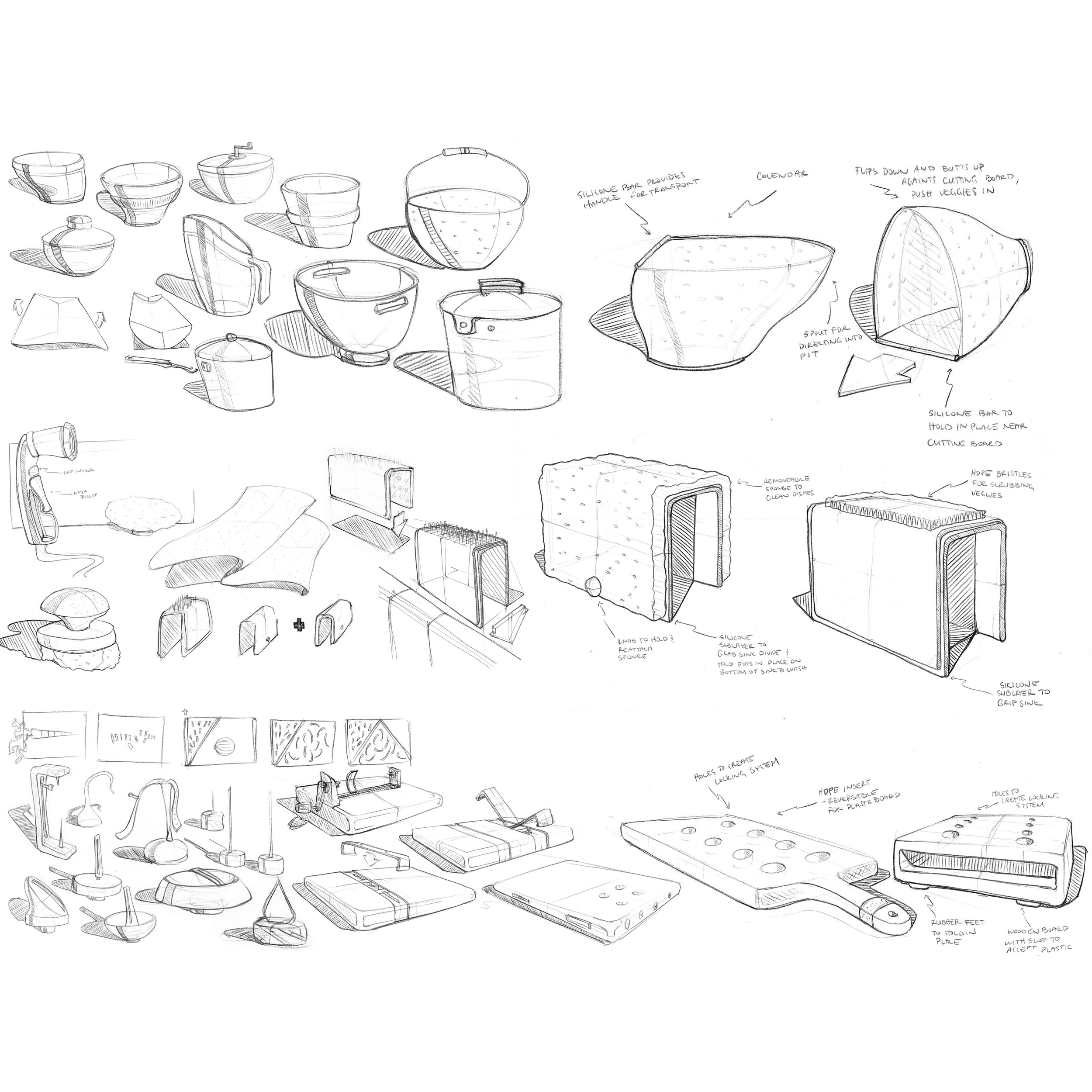

Ideation

I jumped into ideation as quickly as possible to lay the groundwork for this family of goods. I paid careful attention to the design motifs each shared, working to create a cohesive line.

Build

Three separate models utilized just about every modeling technique I knew - CNC milling, 3D printing, laser cutting, the use of various woodshop tools, cabriole forming, sanding, etc. You name it, I probably did it for this project.

The Products

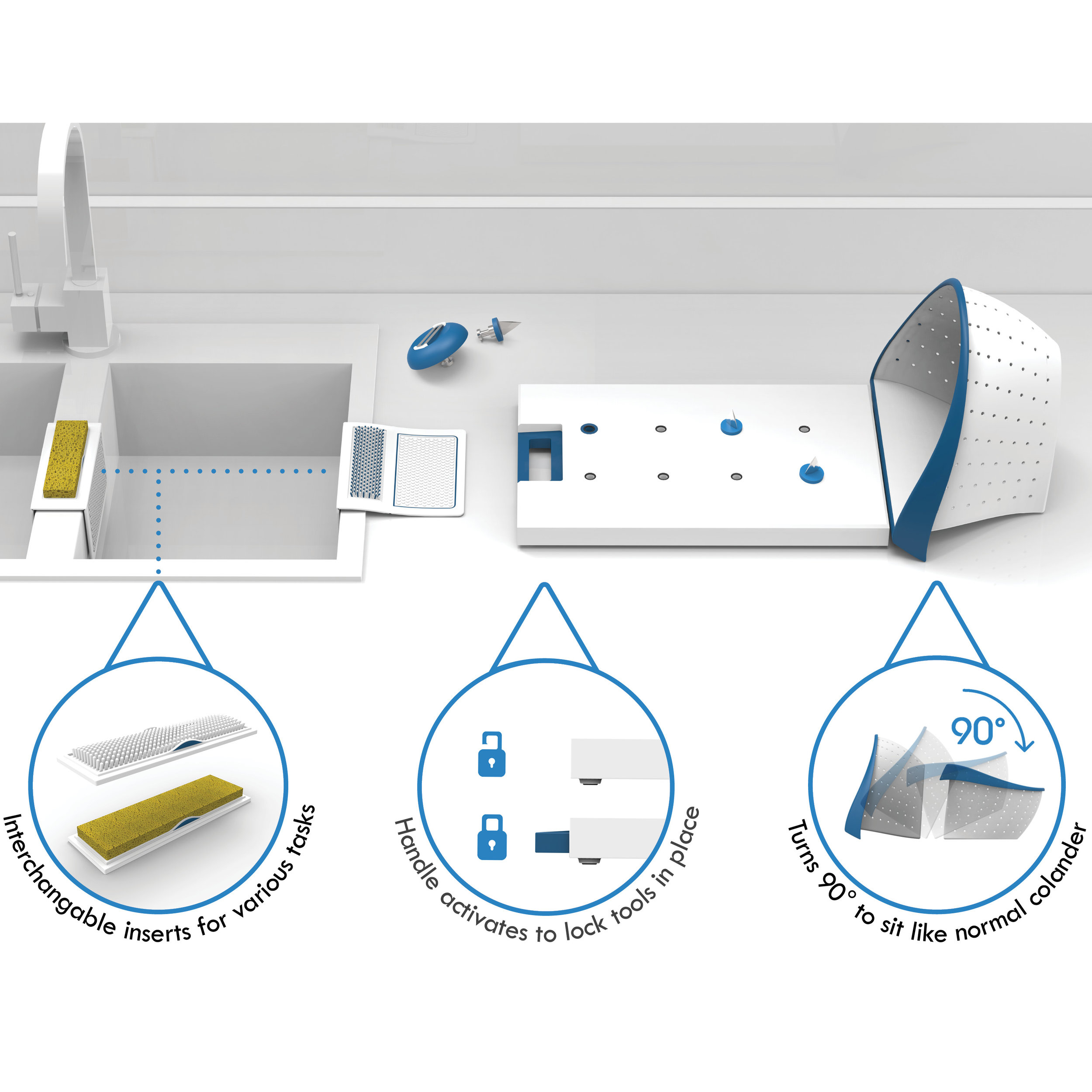

Scrubber - a silicone matt with interchangeable heads, this scrubber works in reverse of many on the market, allowing the user to leave the scrubber stationary and move them item on top of it. The silicon base holds it steady as the action is performed

Cutting Board - equipped with accuating keyhole slots, this cutting board makes it easy to switch various tools in and out, letting your cutting board do all of the holding. A simple two piece design, clean up is made easy.

Colander - built to work in tandem with the cutting board, the colander pivots 90°, butts up with the board, and allows for easy scrapping of cut items straight into the colander. Pivot it up and head to the sink for easy rinsing.

Examples of the many potential tools, the veggie peeler and item skewer plug into the cutting board and seal tightly to the surface, locking in place as you engage the keyhole mechanism by pulling the handle.

Final Models

The reality of a small scale project is that these models were the only ones produced. These ideas more than likely won’t directly help Mr. Smith, but I’d like to think that with the right support, they’ll have the opportunity to eventually serve their purpose.